Venting a custom hood when it is impossible to vent outside

You want a cool custom hood above your range or cooktop in your new kitchen, but you have no way to vent one. This situation would arise in condominiums or homes that have the range located on an inside wall and framing does not allow for a vent pipe.

I recently had a client who at the time of building her new home was undecided on what she wanted to do about ventilation above the range. The plan had a vented hood penciled in, but no firm plans. A year after her house was completed (this is a secondary home not a crucial element of everyday life), she contacted me that she wanted to have a curved wood hood made with a stainless ventilation insert.

The builder did not install a vent pipe of any kind during construction and at this point my client was told that there was no way to install a vent pipe of any size. This required hood ventilation to be “recirculating”. This creates a limitation of the hood ventilation inserts that can also be used with a re-circulation kit. Also, the air has to be recirculated back into the room with these types of kits.

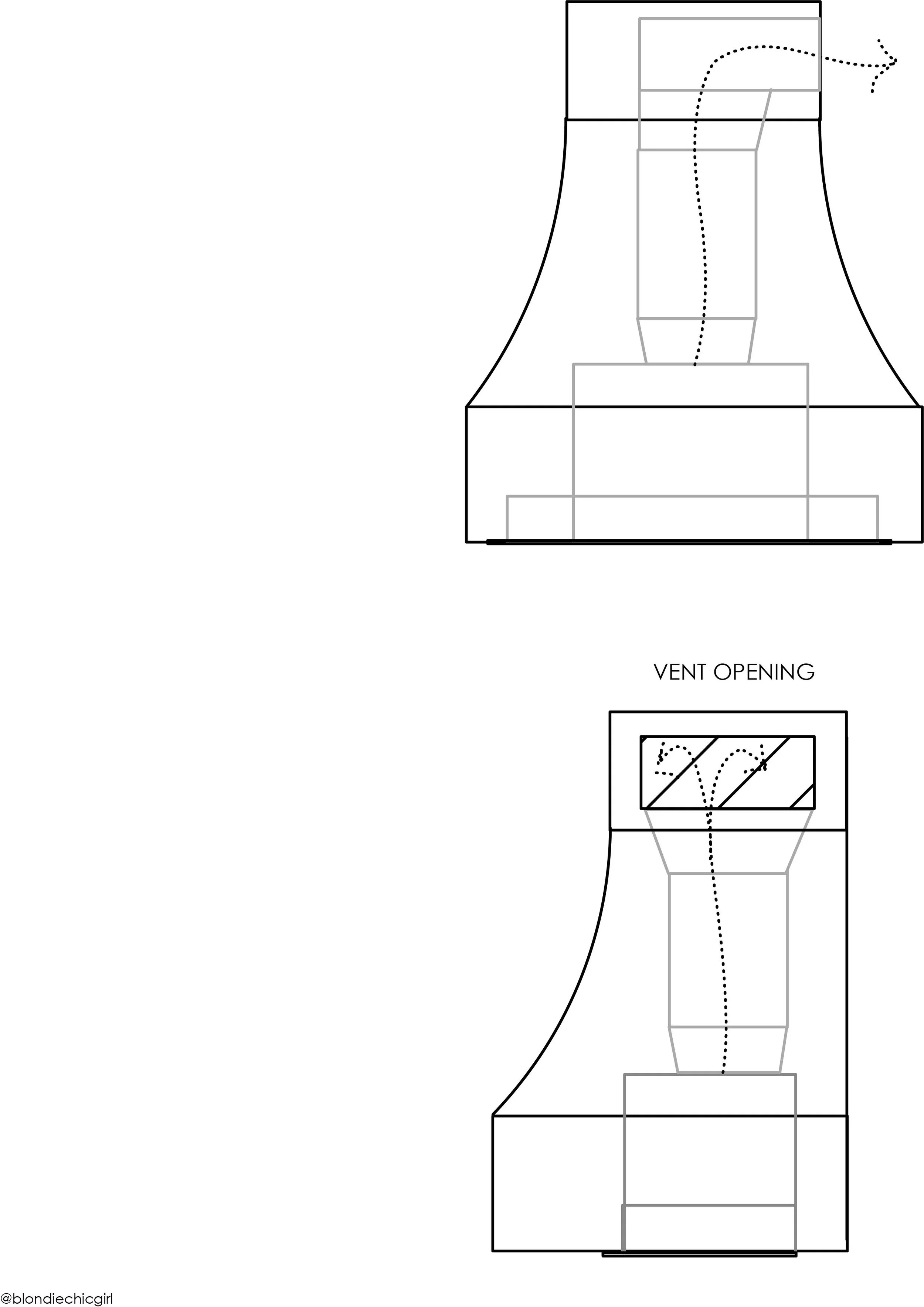

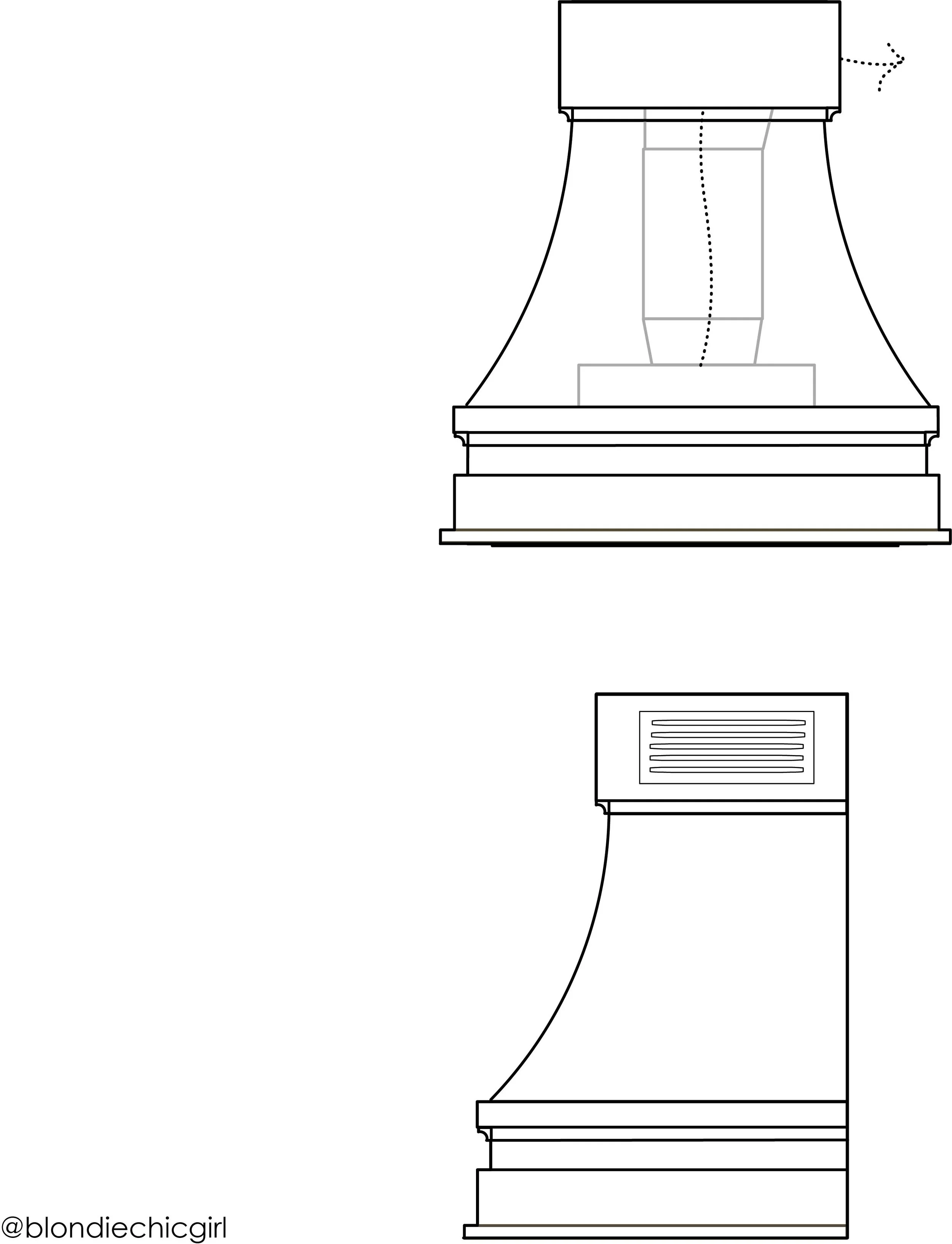

Fortunately I realized that the hood would need to be vented out of the top of the hood somehow. In this design, there is no cabinetry directly adjacent to the top of the hood. The 2 options were to vent the hood out the front at the top or to vent the hood to the side at the top. The design was a curved hood - the hood got narrower from the bottom to the top of the hood. The design needed to accommodate the vent pipping and the 90 degree vent boot that was designed to vent out the top to the right.

Since there was little room for error in building the hood, the factory wanted the hood insert on site in order to build the hood. The technical drawings from Broan were not thorough enough. The hood is inserted and then vented up and to the right at the top of the hood. If cabinetry butted the hood, then the hood would have needed to be vented at the top of the hood. By being able to vent at the top to the side, makes the hood more appealing.

To finish off the vent opening, a wood grill was fitted and painted at the factory to match the hood. The wood grill was fitted into the top detailing. The top molding had to be part of the hood because the opening and grill was integrated into this detail. Taking time to think through every element of design of the hood is essential - if the piping would not have fit - it would have been an expensive mess.

Design Tips for a Recirculating Custom Hood

Ventilation

In relation to the kitchen design, where can the hood be vented back into the room? At the top of the hood - either in the hood or a soffit (not a fan of soffits, but if there is already one there….) or can the hood be vented to the side? For the hood to be vented to the side, there must not be any adjacent cabinetry.

Hood Design

The curved hood in this illustration is probably the most difficult design for a recirculating hood. The hood must get smaller at the top and accommodate the vent pipes and 90 degree boot. A hood with a rectangle design/boxy design would be much more straight forward for the vent piping. The cut out for the vent is ideally done while building the hood, not at the time of installation. Otherwise the hood could be butchered.

Other Thoughts

How will the venting look in relation to the kitchen?

How can the vent open design be minimized to not be in your face?

If this is in a kitchen that gets used a lot, will the recirculating vent air affect other elements: cabinetry, lighting, etc. This may be a question that you pose to the manufacturer of the hood insert.

Make sure all avenues to vent outside have been exhausted and not possible. The best function of any range ventilation system is outside ventilation.

If you are building a new construction home, always put in a vent pipe to the outside even if you are not sure if you need it. This is generally pretty straight forward at the time of construction. Sometimes builders can be “lazy” about this -you may need to push the issue to come up with solutions. When the house is being designed, all ventilation should be considered at that point also.

I learned a lot in designing this hood. It took time and collaboration with the factory. Whoever is designing and building your kitchen will need to be thorough and an out of the box thinkers for such a custom hood to be successful.